VIBRATION SENSOR

One-stop solution for Assembly line for automotive, GI and Aerospace industries.

WIRELESS SENSING SOLUTION – VIBRATION SENSOR

- Battery-powered wireless sensors make it possible to monitor environment and equipment remotely with minimal installation effort.

- Collected sensor data can be used for condition monitoring, predictive maintenance, productivity optimization and energy savings in commercial and industrial fields.

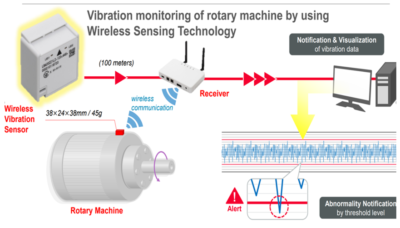

- It is installed on the rotating equipment such as pumps and fan motors, and detects abnormalities by vibrations.

- Sensor data can be managed for PC collectively.

FEATURES

- Notification and alarm system when there is fault in any rotator or pump.

- Integration with machine PLC based on the data generated by sensors and trigger.

- Tower light or stake light integration.

- Sensor management system and Dashboard (customized software by Autologiq).

- Work station with alarm system and PLC , connection topology.

BATTERY LIFE OF SENSOR

- Long operating life enabled by low power consumption design

- Reference information (not a guaranteed value)

- Battery life depends on report interval.

- Simulation based on operation at nomianl temperature of 25 degree Celcius.

BENEFITS

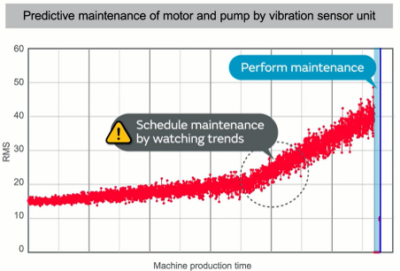

- Early detection of equipment abnormalities

- Prediction of malfunction

- Monitor machine condition

HOW TO INSTALL

- Vibration Sensor Unit can be easily installed without stopping the machine, through a strong magnet located on the bottom of unit

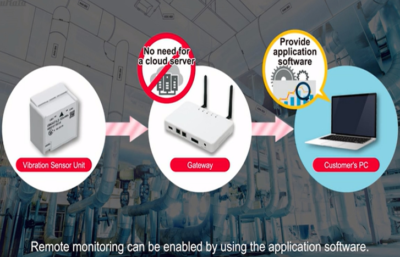

- Remote monitoring can be achieved by just connecting a vibration sensor unit , gateway and your PC

- Installation of alarm and warning light with the PLCS of the machine if requirement by customer( requires programming)

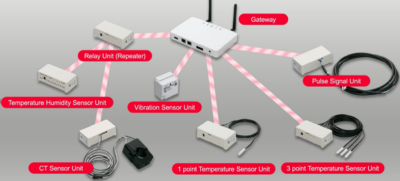

EXTENSIVE LINEUP

- You can select a sensor unit and add it after installation of gateway.

For more information, please kindly contact Autologiq team or request a consultation.