ABB ROBOTICS

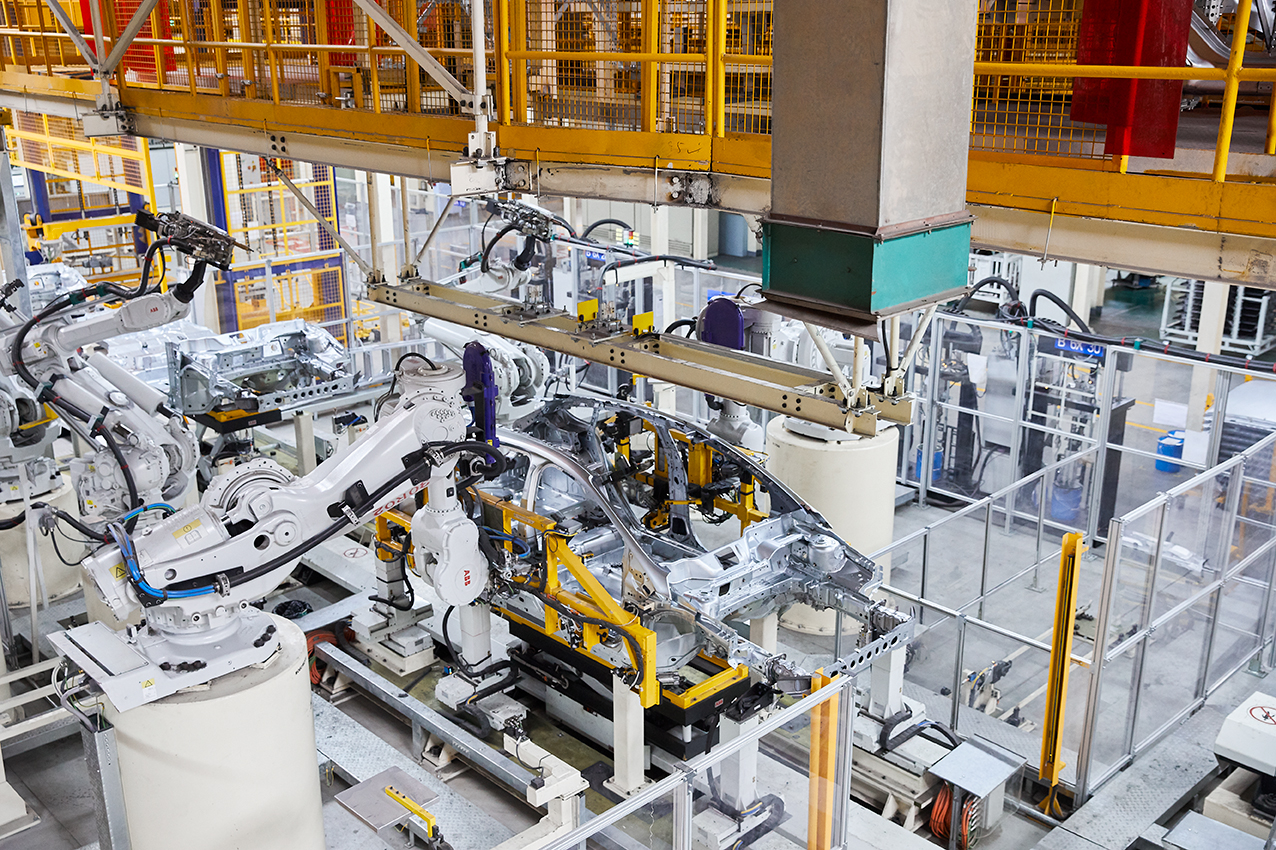

One-stop solution for Assembly line for automotive, GI and Aerospace industries.

ENHANCE PRODUCTIVITY IN EXTRAORDINARY NARROW SPACE

.

ROBOTS AND SOLUTIONS

ABB Robotics as one of the world’s leading robotics and machine automation suppliers is the only company with a comprehensive and integrated portfolio covering robots, AMRs and machine automation solutions – designed and orchestrated by our value-creating software.

ABB Robotics employs approximately 11,000 people at over 100 locations in more than 50 countries.

Industries we serve:

- Automotive

- Construction

- Education

- Electronics

- Food & Beverage

- Foundry & Forging

- Healthcare

- Logistics

- Metal Fabrication

PRODUCTS

.

IRB 1410

- A handling capacity of 5kg at the wrist with a unique 18kg additional load for applications equipment on the upper arm.

- Integrated wire feed cabling and mounting holes for optimized assembly of process equipment on the arm.

- Easy-to-use arc welding functions are included as standard in the IRC5 robot controller are made available via the patented programming and operation interface unit – the FlexPendant.

- Arc Welding, Material Handling, Machine Tending.

SWIFTI™ CRB 1300

- With a TCP speed of over 6 m/s, it is 6 times faster than other cobots in its class

- Up to 10 times higher position repeatability 0.01 mm than most cobots in its class

- Interaction status light

- SafeMove + SICK laser scanner included

- Simple yet powerful Wizard easy programming

- Four integrated air supplies enable vacuum picking

- Industrial robot quality and reliability

- IP40

- Full safety certification

https://webshop.robotics.abb.com/gl/swiftitm-crb-1300-assembly-set.html

AMRs

- Reception – Warehouse – Shipment

- Intralogistics

- Material handling

- Line supply and kitting

- Assembly and sub-assembly lines

- End of line handling – Auxiliary supplies

- Interprocess connection

- Goods to robot G2R – Robot cell feeding

- Pallet to palletizing/depalletizing cells

https://new.abb.com/news/detail/95036/prsrl-abb-rebrands-autonomous-mobile-robot-portfolio

High Speed Alignment

- Speeds up productivity by 70% in highly accurate alignment applications with 6 axis robots.

- Effortless commissioning with auto-calibration and tuning, reducing deployment time from 8 hours to just 1 hour.

- Designed for highly precise assembly lines that require 0.01 – 0.02 mm accuracy levels.

- Easy-to-use software and intuitive user interface, little expertise required to operate the system.

- Compatible with a wide range of cameras, IRC5 and OmniCore™ robot controllers for high flex-ibility.

https://new.abb.com/products/robotics/application-software/assembly/high-speed-alignment

For more information, please kindly contact Autologiq team or request a consultation.